Hello,

I'm developing a torque meter using nrf82832 I fixed complete wheatsotne bridge in my metal part that need measure deformation, but each time that I assemble or disassemple or thighten the screws, the value of adc is changing..

Below, the saadc configuration that I'm using:

void saadc_init(void) {

// SAADC config & calibrate

nrfx_saadc_config_t saadc_config = NRFX_SAADC_DEFAULT_CONFIG;

APP_ERROR_CHECK(nrfx_saadc_init(&saadc_config, saadc_event_handler));

while (nrfx_saadc_is_busy())

sd_app_evt_wait();

// Channels config

//Bateria

nrf_saadc_channel_config_t battery_config = NRF_DRV_SAADC_DEFAULT_CHANNEL_CONFIG_SE(NRF_SAADC_INPUT_AIN0);//NRFX_SAADC_DEFAULT_CHANNEL_CONFIG_SE(NRF_SAADC_INPUT_VDD);

APP_ERROR_CHECK(nrf_drv_saadc_channel_init( 0, &battery_config));

//Celulas de carga

nrf_saadc_channel_config_t cell_config = NRF_DRV_SAADC_DEFAULT_CHANNEL_CONFIG_DIFFERENTIAL(NRF_SAADC_INPUT_AIN4, NRF_SAADC_INPUT_AIN7);

cell_config.reference = NRF_SAADC_INPUT_AIN5;

cell_config.gain = NRF_SAADC_GAIN1_4;

APP_ERROR_CHECK(nrf_drv_saadc_channel_init( 1, &cell_config));

// double buffering

APP_ERROR_CHECK(nrfx_saadc_buffer_convert(buffer[0], INPUTS));

APP_ERROR_CHECK(nrfx_saadc_buffer_convert(buffer[1], INPUTS));

}

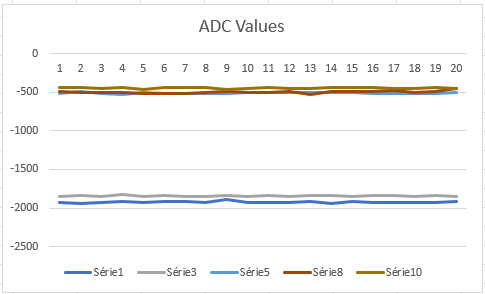

The values read from the adc each time I modify the mechanical part

Just electronic boad

<info> app: -1924.00 <CR><LF>

<info> app: -1936.00 <CR><LF>

<info> app: -1930.00 <CR><LF>

<info> app: -1914.00 <CR><LF>

<info> app: -1926.00 <CR><LF>

<info> app: -1920.00 <CR><LF>

<info> app: -1918.00 <CR><LF>

<info> app: -1928.00 <CR><LF>

<info> app: -1886.00 <CR><LF>

<info> app: -1930.00 <CR><LF>

<info> app: -1924.00 <CR><LF>

<info> app: -1930.00 <CR><LF>

<info> app: -1920.00 <CR><LF>

<info> app: -1936.00 <CR><LF>

<info> app: -1920.00 <CR><LF>

<info> app: -1932.00 <CR><LF>

<info> app: -1932.00 <CR><LF>

<info> app: -1924.00 <CR><LF>

<info> app: -1928.00 <CR><LF>

<info> app: -1912.00 <CR><LF>

<info> app: -1930.00 <CR><LF>

Just first metal borad part with the screws

<info> app: -1850.00 <CR><LF>

<info> app: -1842.00 <CR><LF>

<info> app: -1844.00 <CR><LF>

<info> app: -1828.00 <CR><LF>

<info> app: -1852.00 <CR><LF>

<info> app: -1838.00 <CR><LF>

<info> app: -1846.00 <CR><LF>

<info> app: -1846.00 <CR><LF>

<info> app: -1838.00 <CR><LF>

<info> app: -1850.00 <CR><LF>

<info> app: -1840.00 <CR><LF>

<info> app: -1848.00 <CR><LF>

<info> app: -1838.00 <CR><LF>

<info> app: -1840.00 <CR><LF>

<info> app: -1852.00 <CR><LF>

<info> app: -1842.00 <CR><LF>

<info> app: -1842.00 <CR><LF>

<info> app: -1844.00 <CR><LF>

<info> app: -1834.00 <CR><LF>

<info> app: -1850.00 <CR><LF>

Just first metal borad part with the screws again

<info> app: -520.00 <CR><LF>

<info> app: -492.00 <CR><LF>

<info> app: -514.00 <CR><LF>

<info> app: -528.00 <CR><LF>

<info> app: -504.00 <CR><LF>

<info> app: -512.00 <CR><LF>

<info> app: -522.00 <CR><LF>

<info> app: -514.00 <CR><LF>

<info> app: -512.00 <CR><LF>

<info> app: -510.00 <CR><LF>

<info> app: -510.00 <CR><LF>

<info> app: -500.00 <CR><LF>

<info> app: -510.00 <CR><LF>

<info> app: -500.00 <CR><LF>

<info> app: -504.00 <CR><LF>

<info> app: -514.00 <CR><LF>

<info> app: -512.00 <CR><LF>

<info> app: -512.00 <CR><LF>

<info> app: -514.00 <CR><LF>

<info> app: -504.00 <CR><LF>

Completely mechanical board

<info> app: -496.00 <CR><LF>

<info> app: -500.00 <CR><LF>

<info> app: -500.00 <CR><LF>

<info> app: -500.00 <CR><LF>

<info> app: -512.00 <CR><LF>

<info> app: -514.00 <CR><LF>

<info> app: -514.00 <CR><LF>

<info> app: -498.00 <CR><LF>

<info> app: -488.00 <CR><LF>

<info> app: -500.00 <CR><LF>

<info> app: -506.00 <CR><LF>

<info> app: -486.00 <CR><LF>

<info> app: -532.00 <CR><LF>

<info> app: -488.00 <CR><LF>

<info> app: -496.00 <CR><LF>

<info> app: -494.00 <CR><LF>

<info> app: -484.00 <CR><LF>

<info> app: -510.00 <CR><LF>

<info> app: -494.00 <CR><LF>

<info> app: -456.00 <CR><LF>

Dissasselmby all parts and assembly mechanical board again

<info> app: -436.00 <CR><LF>

<info> app: -442.00 <CR><LF>

<info> app: -450.00 <CR><LF>

<info> app: -434.00 <CR><LF>

<info> app: -460.00 <CR><LF>

<info> app: -440.00 <CR><LF>

<info> app: -444.00 <CR><LF>

<info> app: -440.00 <CR><LF>

<info> app: -466.00 <CR><LF>

<info> app: -458.00 <CR><LF>

<info> app: -440.00 <CR><LF>

<info> app: -448.00 <CR><LF>

<info> app: -450.00 <CR><LF>

<info> app: -444.00 <CR><LF>

<info> app: -440.00 <CR><LF>

<info> app: -440.00 <CR><LF>

<info> app: -454.00 <CR><LF>

<info> app: -448.00 <CR><LF>

<info> app: -444.00 <CR><LF>

<info> app: -446.00 <CR><LF>

Others values of my electronic circuit:

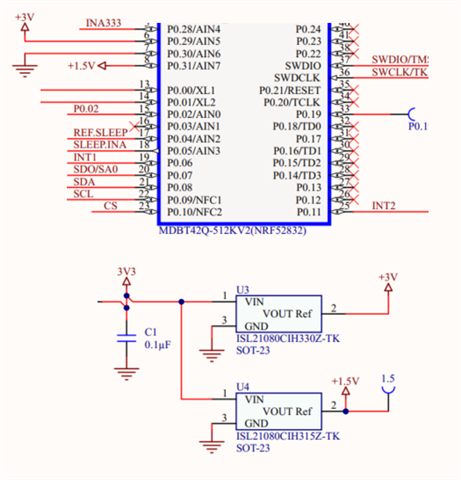

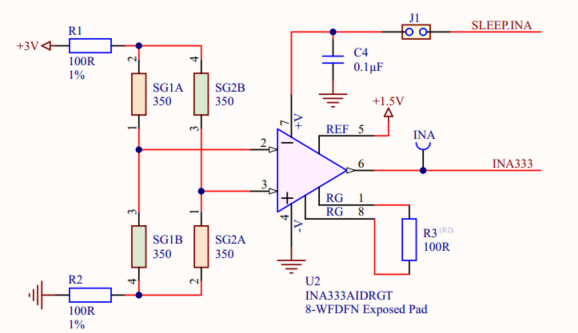

Brigde: 3V supply using Vref3v (ISL21080CIH330Z-TK)

Using INA333 with gain 1000 and reference with 1.5V supply with Vref1.5V (ISL21080CIH315Z-TK)

The wheatsone bridge using 350ohm strain gauges

Anyone help me if I need change any SAADC configuration?

Regards

Laerte