Dear Nordic Semiconductor Support,

We are experiencing an issue with our NRF52832 chip while performing ADC reads in a Zephyr environment. Our setup involves two ADC channels: AIN2 for battery voltage and AIN3 for a Force-Sensing Resistor (FSR). The FSR is sampled more frequently than the battery voltage.

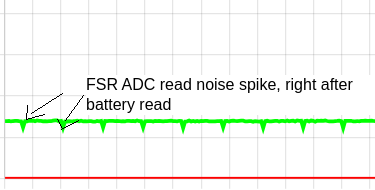

When we perform a battery voltage read on AIN2, the subsequent FSR sample on AIN3 contains significant noise. If we discard the first sample after the battery read, subsequent FSR samples return to normal levels. If the battery voltage ADC reads are not performed, the noise issues in the FSR reads are not observed, this issue does not occur if the battery voltage reading is disabled.

Could you please provide insights or suggestions on how to resolve this noise interference between the two ADC channels? Any recommendations for ADC configuration settings or sequencing that might mitigate this issue would be greatly appreciated.

Best regards,

Pedro