Hello,

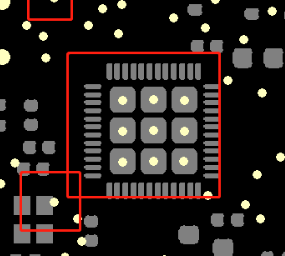

I am using the NRF52832 in my PCB design, and I have attached a screenshot of relevant part of the layout. My PCB manufacturer pointed out that some vias overlap with the pads of the NRF52 (in the center ground pad area), and they suggested filling these vias with resin to improve soldering reliability and prevent solder wicking during assembly.

Before I proceed, I wanted to ask the following:

- Is resin-filled vias (via-in-pad) a common practice for NRF52-based designs?

- Are there any potential issues (thermal, mechanical, or electrical) specific to the NRF52 when using resin-filled vias in the ground pad region?

- Does Nordic have any specific recommendations regarding via treatment (like tenting, plugging, or filling) for the ground pad under the NRF52?

- Would this affect thermal performance or solder joint integrity in any way, considering the device's requirements?

Thanks in advance for your input!

Ron