What is the power consumption to check battery level?

How quickly at boot time is an accurate battery state of charge available?

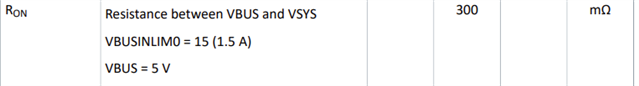

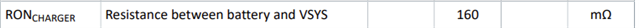

What is the RDSon in the path from VBUS or VBAT to VSYS? (Assuming there are either internal diodes or a FET for protection)

Can the VSYS of one nPM1300 be used to power the VBUS of another nPM1300 (chained together)?

Is there a trade off of accuracy of the battery level if the voltage, current and temp are read less frequently? What is least often the state of charge can be checked to maintain accuracy?

How fast can the state of charge be updated?

How does nPM1300 handle aging batteries? Is it possible to profile a battery at 5 stages, early life, 1/4 life, half and 3/4 life and end of battery life and generate 5 different profiles and load the right one for the application as the battery ages? Will this accurately reflect battery aging?