Hello,

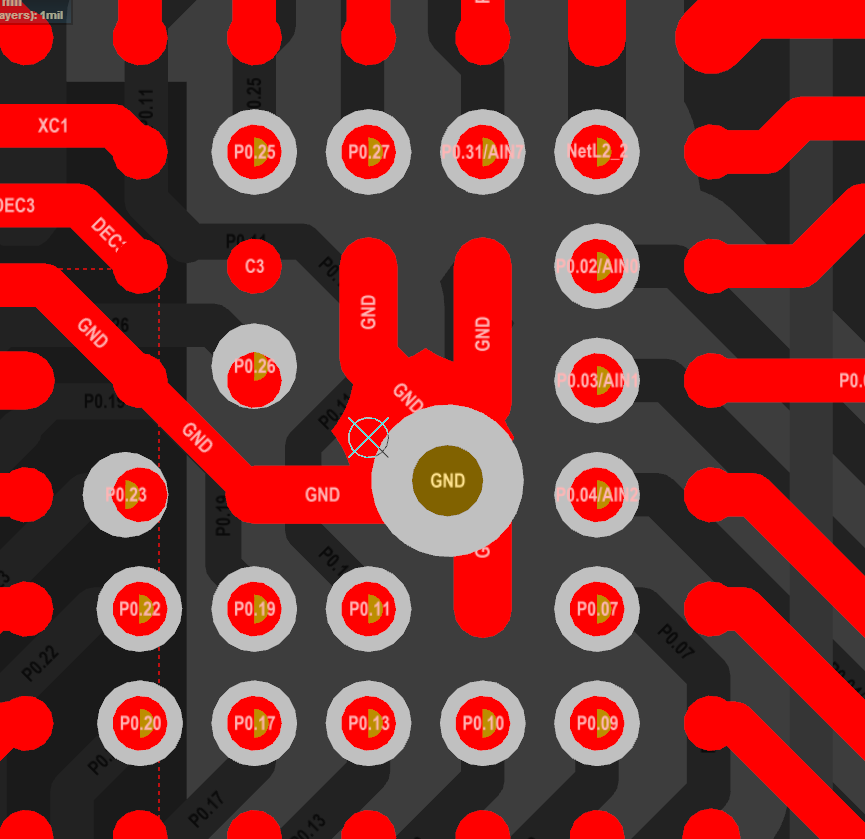

We recently sent a design to our board assembly house for review and they indicated that the large copper area under the nRF528323-CIAA (WLCSP) may result in head-in-pillow or cold solder joints.

There reference design specifies a copper in the inner area of the footprint:

Our PCB assembler indicates that the large copper area might cause manufacturing issues.

Q: There is large area of copper among PAD of U6, this may cause the soldering joint not welding well or the possibility of Head-in-Pillow(HIP).

IF this design is considering the factor of heat dissipation, SMT may proceed with the current design accordingly, then provide the improvement action after trial run.

What is the reason for the additional copper area? Is the copper required for thermal dissipation?

Thank you,