Hi,

I've developed nRF52832 chip for our company's application,

and I found some weird phenomenon

we using nRF52832 chip with Nordic softdeivce and SDK v12,

BLE chip operates with DCDC converter (internally),

The power is supplied by 3V coin cell.

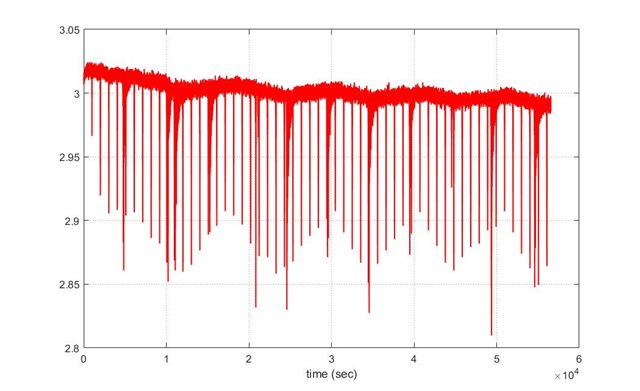

The above figure shows VDD voltage of BLE chip. Those values measured by SA-ADC module in BLE chip

every 1 second, and our custom hardware keep stored in refrigeration room (about -20 C).

As you could see, the VDD value have dropped every certain period. The period is about 1024 secs.

Anyone knows that? why this phenomenon is being observed..?

Thank you for your helps

- Daewoong Kim