Hi,

So I was using nRF52810 with epoxy or resin coated,but actually the signal quality did not match my needs, the signal faded about 20dB compared to the device which not coated.

In order to provide a proper match, the antenna manufacturers designed several antennas to match the device which are coated.But the signal is not getting better.

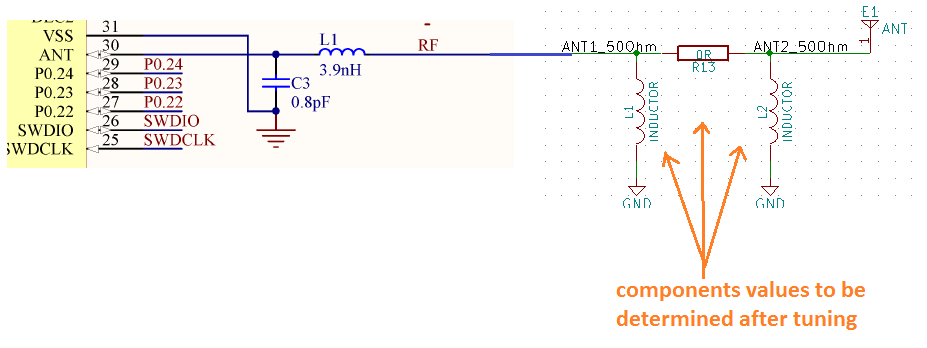

And also we try to adjust PI network to match which are coated, the network analyzer shows that the frequency point falls at 2.4GHz. But actually the signal is not getting better. When we adjust PI network, L1 and C3 are still soldered.Can they be replaced?

Is that possible the examples of epoxy or resin are not appropriated?Can you perhaps suggest a few suitable examples of an epoxy or resin to coat the CEAA package with?