Hi :) ,

I'm using TWI to connect a sensor that i supply with an LDO regulator.

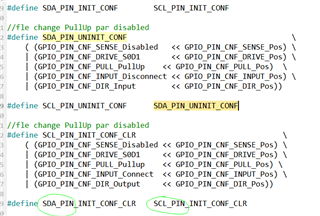

This LDO has an enable pin controlled by P0_23. Driving current is max 1uA so i configured my GPIO in S0S1 mode.

When i start my application i can control properly the LDO with this EN pin.

P0_23 = 0 -> LDO output =0V

P0_23 = 1 -> LDO output =2.6V (fixed output voltage of my reference).

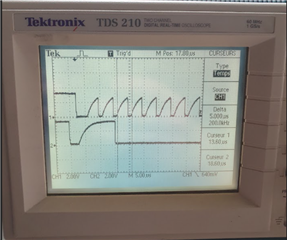

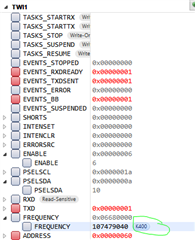

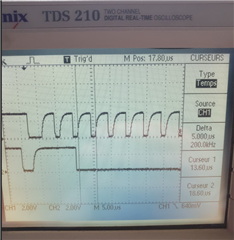

But a strange behavior happen when i init TWI module with: twi_init() .

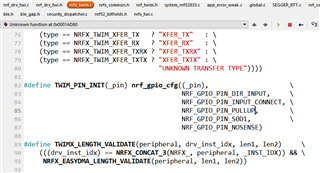

Once the line err_code = nrf_drv_twi_init(&m_twi, &twi_sensors_config, twi_handler, NULL); i executed, my LDO regulator voltage output goes to 1.7V.

Note that mu uC supply is 3.3V.

So i test to use twi_uninit() when i measure 1.7V, and magic, the LDO output goes low as if my TWI was controlling P0_23...

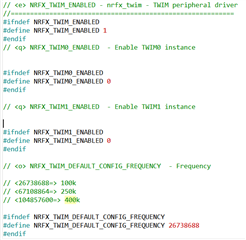

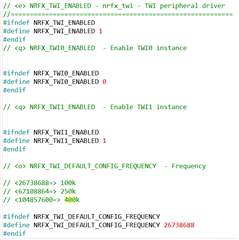

SCL and SDAZ are connected to the two NFC gpio that i disabled in the pre processor definition of the project. P0_10 and P_26.

The PIN_CNF of P0_23 doesn't change when i twi_init.

Is ther eany link that i missed somewhere between P0_23 and TWI module please ?

Thanks a lot