I am trying to measure current consumption with different setups on nrf52dk_52832 such as humudity, temperature sensors etc.

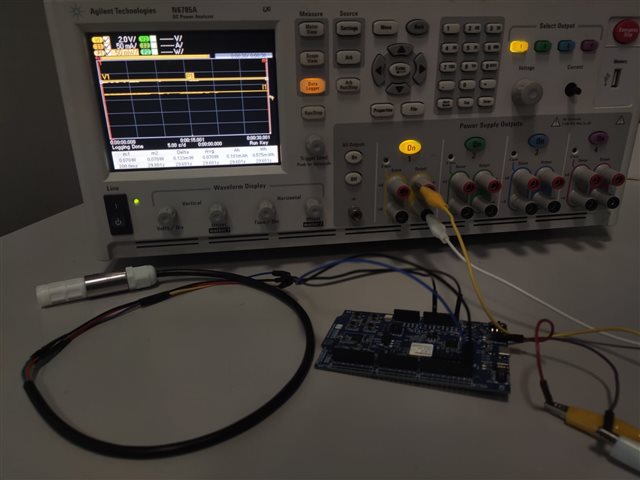

To do that i plug dc power analyzer to external supply pins after cut sb9 and soldering sb12. My main assumption is if dc power analyzer gives 3V to nrf52dk and i run with this, i should see correct results for current consumption analysis.

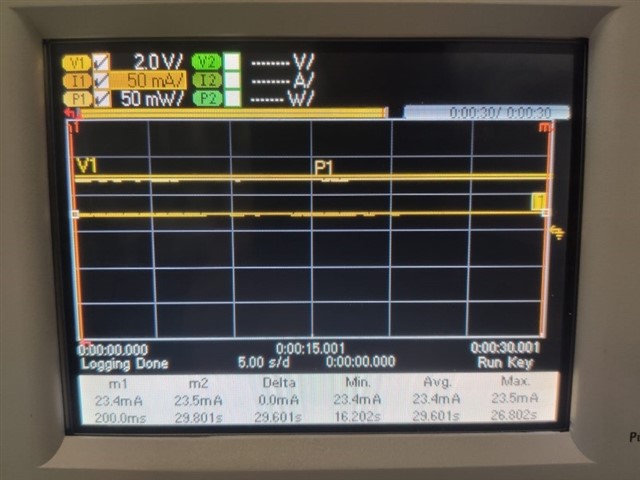

But it gives approx. 23mA average and i can not decrease it. Even in idle(by erasing memory) it is 28mA average with this measurement method.

My questions are:

1- Is my measurement method wrong?

2- If so, or even if not, What are other ways to measure average current/power consumption?

3- How can i decrease average current/power consumption to make my battery last longer?

4- Also, What is power cycling in "After programming the nRF52832 SoC, the USB must be disconnected and the DK power cycled to reset the debugger chip before current measurement."?

Thanks in advance.