hi

We have developed it to the specifications below and are preparing for mass production.

We would like to inquire about a 10% standby current test defect occurring in pre-production (100EA).

1. Specifications

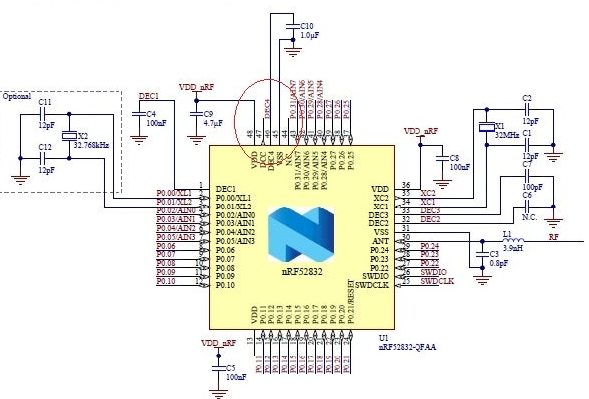

- nRF52832

- SDK 17.1.0

2. Self-review results

- PCBs with standby current defects continue to defect (100%)

- Normal PCB with no standby current defects continues to be normal (100%)

- If you retouch the nRF52832 IC with a heat gun, the standby current will return to normal for a while and then increase again.

- Changing peripheral devices such as crystal, LDO, etc. does not solve the problem.

- Normal current: 100uA -> defective PBA 230uA

=> Is there anything you can guess as the cause?