Hi,

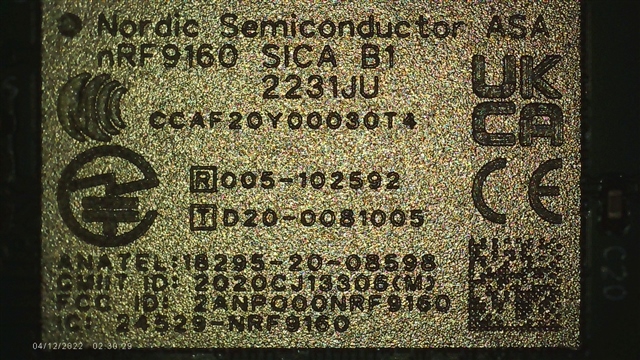

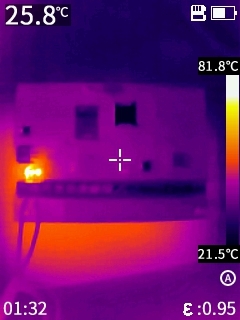

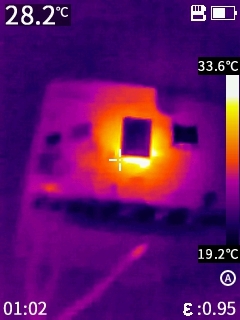

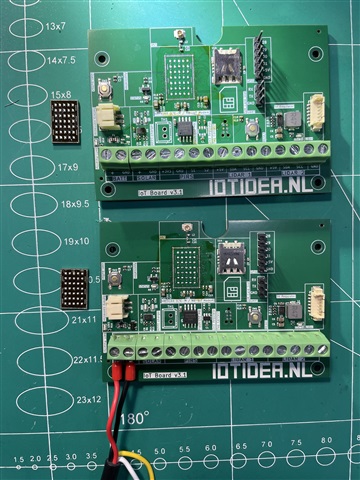

I am working on a custom PCB. I ordered them at JLCPCB and I have some issues with the soldering. I noticed in a few boards there is a short in the board between the NRF VDD line and GND. Using a thermal camera I found out there are multiple boards with multiple components getting hot when injecting power with limited current.

I set the power supply to 3,8V and current to max 80 mA. All shorts are gone when i removed the NRF9160 from the board by using a pre heater and hot air.

I also added the Gerber file. Is there anything I can do to improve solderability to this design?

Thanks!