Hi,

as my project moves forward I've switched to development of central board. In addition to space restrictions the board is promising to be a resource hog. A 2500+ mAh battery is a must, and after some review I chose 18650 as cheap and compact solution. However, due to number of components an FR4 board doesn't fit the size well. After number of unsuccessful attempts I've started to consider fully flexible PCB for my design. Again, as with the peripheral part the RF is something which must be considered in the first place. To keep things weirder I'm planning to put antenna and nRF52832 on different parts of the board :-)

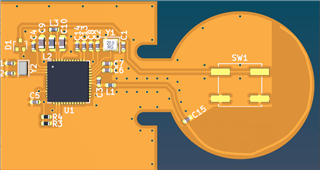

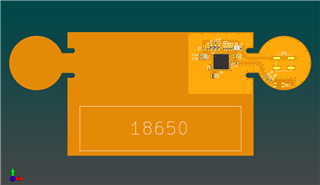

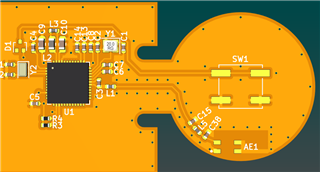

So here is the design: take a 18650 battery, wrap the board around it, then cover battery ends with leafs from the same FPCB. The leafs should have a stiffener. In order to assemble the thing add two plastic caps on the battery - they will align main board and fix the leafs. The result cylinder may be placed inside aluminum tube and sealed with two external plastic caps. Because of the tube the only shield free areas on the device are the ends. Such my antenna (and button) were placed on one of the leafs, and MCU resides on the main board:

I requested exact specs for materials used in manufacturing process, still wait for reply. For the draft I assumed adhesiveless 75 um polymide, 1 oz/sq.ft copper which resulted in 0.17 mm track width to match 50 Ohm impedance. The antenna in subject is Johanson 2450AT18D0100.

And if you won't mind a number of questions, of course:

- Although the idea to employ FPCB isn't new, what do you think about the proposed design? Is it prone to RF issues? What may be recommendations to it?

- It looks like there is plenty of space for a radial monopole, but I'm concerned about the button in the same area. Taking in account the battery would it be better to stick with a chip antenna anyway?

- As a followup to the previous question, because of the battery should I look for a zero clearance chip antenna instead? Like the Johanson 2450AT42E0100. It has worse gain and seem will require some cheating like no ground on bottom layer and use battery negative for that kind.

- The matching network for the nRF52832 is a replica of the reference design. For flexible PCB component values have to be adjusted. Would it be possible to do with your help?

- Another question is should I tweak tracks width as well? In particular, connection between C3 and L1 doesn't look right to so thin substrate.

Gerber files attached. The circuit (and hence designators) were copied from the reference design (the only difference: R3 and R4 are I2C pullups, please ignore; D1 is used to share the SW1 button between nRF52 and battery management IC).

Thank you!