Hello All,

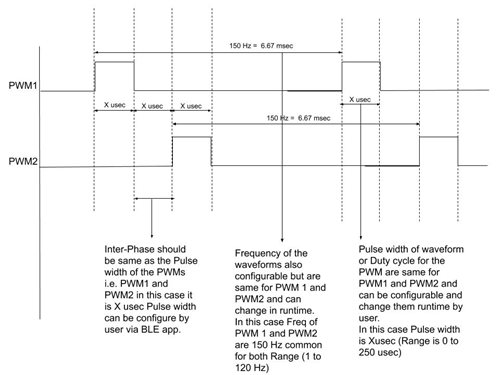

I want to generate Bi-Phasic two PWMs with 180 degree interphase delay and variable Duty Cycle with variable frequency upto 250 Hz in nRF52810 SoC.

Can you please suggest the mechanism as far as firmware programming is concerned!

Thank you in advance