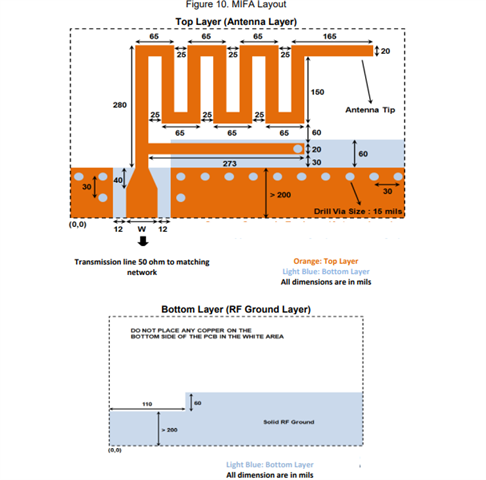

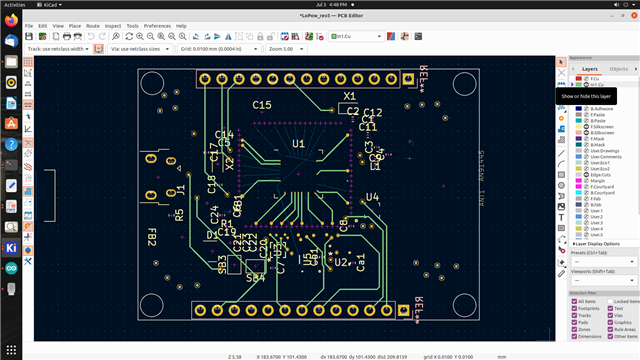

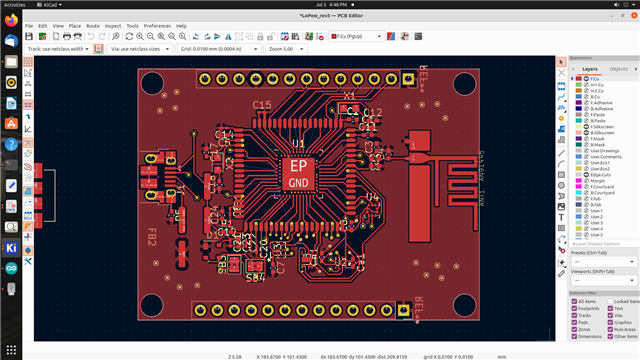

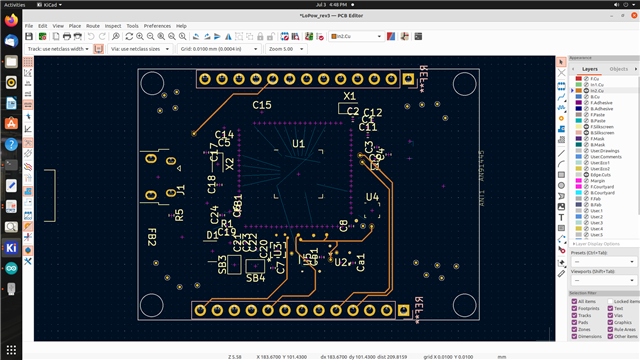

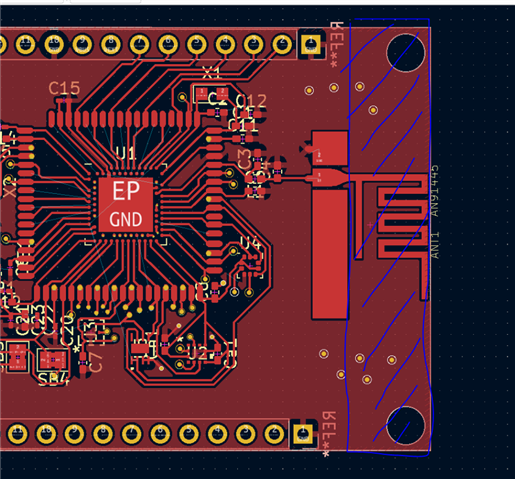

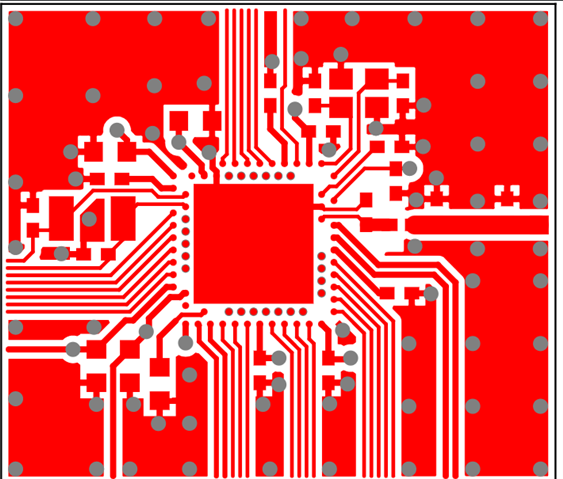

I have designed single layer pcb for the first time using kiCAD software for low power (1-5mW) wearable electronics using nRF52840,one accelerometer sensor i.e.BMA400,one recommended antenna(AN91445) and one 2x5 programming port. Please refer to the attached the document. Please suggest any correction and a suitable program/code so that we can test it using ARM Segger Studio.Low power basic Reference.pdfLow power basic1.0.csv