Hello,

i'm going crazy trying to solve an issue involving I2C communication. I have the following setup:

- ncs 2.4.2 (can't upload to latest because i have an issue with that...i have an issue open on DevZone)

- NRF5340DK

- I2C sensor A (TCS3400)

- I2C sensor B (MCP9808)

- I2C sensor C (LSM6DSOX)

- I2C sensor D (FDC1004)

I developed all the libraries to communicate with these sensors (yes, i know that many of them are supported by Zephyr but drivers were lacking many features such as interrupt, etc.). All the libraries have been tested arranging the breakouts of the sensors on a breadboard.

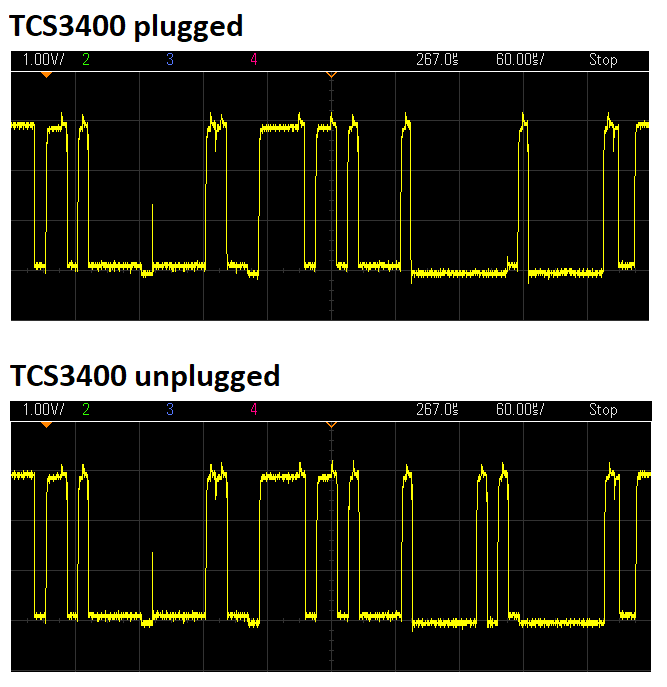

Now, this is the problem: when i try to read data from the FDC1004 (using the required sequence of commands: trigger measure -> check if measure is done -> read measure) AND the sensor A is connected, the "MEASURE_DONE" bit is NEVER set. Please note that the I2C function that reads the register is working (i can read the register content and all the other bits are correctly set). If i unplug the SDA or SCL or VDD for the breakout of sensor A the MEAS_DONE bit is instantly set.

Please note that:

- Connecting or disconnecting sensor B and C is totally irrelevant. If they are connected they work fine, if they are disconnected i still have the exact same problem with A and D. This exclude any problem about the loading of the SDA/SCL paths. Moreover, as i said, ALL the functions with ALL the sensors are working, with the exception of the function "isMeasDone()";

- The only function with this strange behaviour is "isMeasDone()". All the other functions set and read all the correct values in all the registers of every sensor;

- Each sensor by itself works with the code i wrote. This means that there are no issues with the addresses and the write/read functions;

- Sensors do not have the same I2C address. I double-checked it and, moreover, i highlight again that i have this issue ONLY with that specific function;

- The TCS3400 breakout is the only one without pull-up resistors for SDA and SCL on the board, but because of the fact that the other sensor breakouts have it, this is not needed. I measured the overall pull-up values (the parallel of all the pull-up of the several breakouts) is 5.2k, so this should be fine;

- Logging is active in the project. This allows me to track any error on the comunication...and there is not.

Unfortunately i cannot share the project because it has tens of source files and would be very unpractical. Here below you can find the definition of the of the function that is giving me trouble. Again, this function works perfectly if sensor A is not connected, so there should be no issue with the code....however...here you go:

bool fdc1004_isMeasDone(fdc1004_measCh_t measNum) {

//Read actual register value

uint16_t regData = 0;

if (fdc1004_read16(FDC1004_REG_FDC_CONF, ®Data) != 0)

return false;

switch (measNum) {

case FDC1004_MEAS1:

return (regData & (1 << 3));

break;

case FDC1004_MEAS2:

return (regData & (1 << 2));

break;

case FDC1004_MEAS3:

return (regData & (1 << 1));

break;

case FDC1004_MEAS4:

return (regData & (1 << 0));

break;

}

return false;

}

int fdc1004_read16(uint8_t regAddr, uint16_t* data) {

// Initialize read and write buffers

const uint8_t wbuffer = regAddr;

uint8_t rbuffer[2];

// Read register

int ret = i2c_write_read_dt(fdc1004_dev,&wbuffer,1,rbuffer,2);

if (ret != 0) {

LOG_ERR("%s error: Failed to read register 0x%0x", __func__, regAddr);

return SENSOR_ERROR_READ_FAILED;

}

// Prepare data to return

*data = rbuffer[0]<<8|rbuffer[1];

return SENSOR_SUCCESS;

}

Just for the sake of completeness, here below is the section of code that is generating my headache:

// Perform measurement on channel 1

fdc1004_triggerMeasure(FDC1004_MEAS1, true);

while (!fdc1004_isMeasDone(FDC1004_MEAS1)) //ISSUE: THIS NEVER BECOMES TRUE WHEN SENSOR A IS CONNECTED!

{

k_busy_wait(100000);

}

fdc1004_getCapacitance(FDC1004_MEAS1, &capLevel);

I'm not able to get out of this on my own. I am not even able to understand if this is an hardware or a software issue. I hope your experience can provide me some hints to solve it.

Thank you,

Frax