Hello,

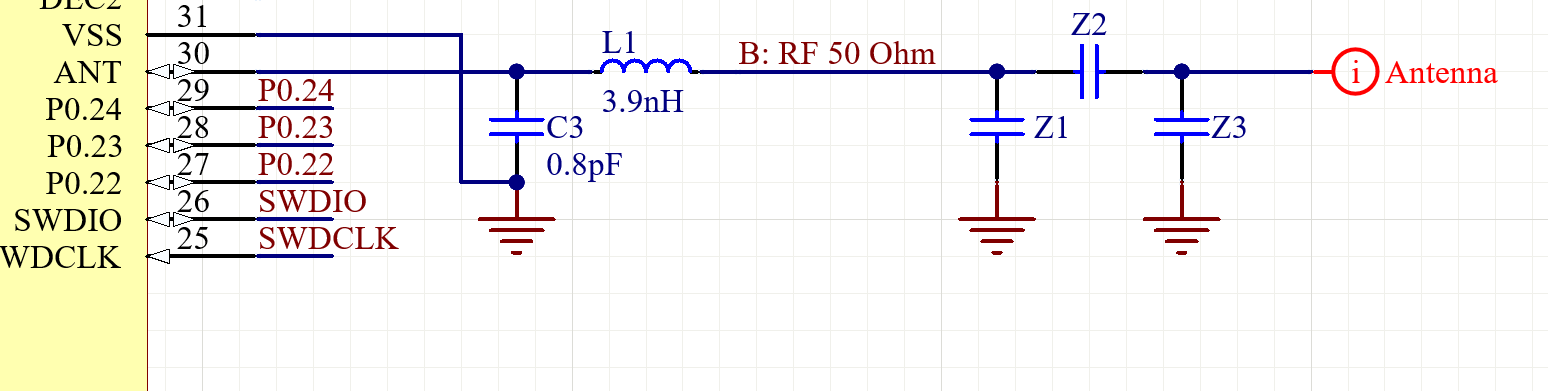

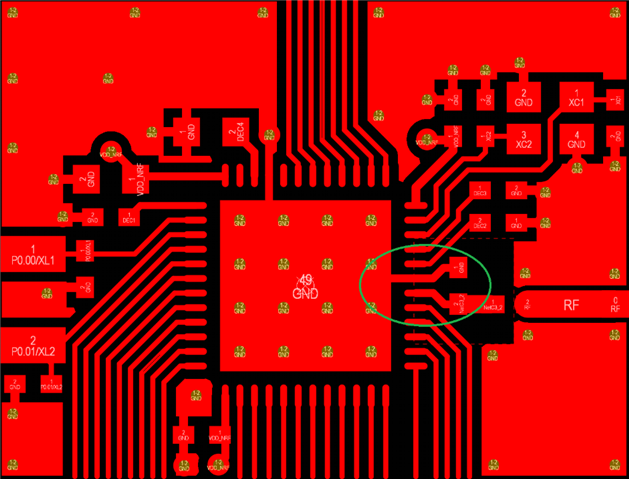

I'm currently creating my own custom board for NRF 52832.

I put everything together, but I can't detect my custom board through Bluetooth using the NRF connect app.

I'm using QFAA and QFAB QFN48 with DC/DC regulator setup.

Here I've attached the schematic of my custom board and all the components.

I'm new to designing an antenna for BLE. I believe there's something wrong with the antenna design.

Please let me know if there's anything wrong with this design.

Thank you!