Hello guys,

I tried to design a pcb antenna for a nrf24l01+, since my company doesnt allow to buy cheap smd breakout board version from china anymore

The pcb stats of the producer:

- 2-layer FR4 1.55mm (61.023mil) thickness, εr = 4.6

- Copper thickness, 35μm (1.378mil)

What I used:

- Guideline for pcb mifa antenna design:https://www.cypress.com/file/136236/download :

Antenna basic dimensions: Page 10

Cutting antenna length to ~115mil as told on page 14 - nrf24l01+ schematic pictured in the datasheet page 66 (rev1.0)

- https://www.eeweb.com/tools/microstrip-impedance for calculation resulting into a feedingline width of 2.82mm (111.023mil), this is double the value of the recommended value in the cypress file. Not sure whats right.

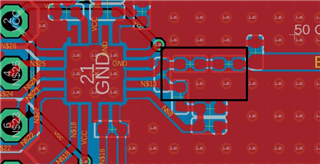

This results into following desgin block:

The antenna area is clear of any signals aswell as ground on top or bottom layer.

Since I have absolutly zero experience with RF antenna design I would like to have some opinions regarding my design.

Thanks so far,

Joe